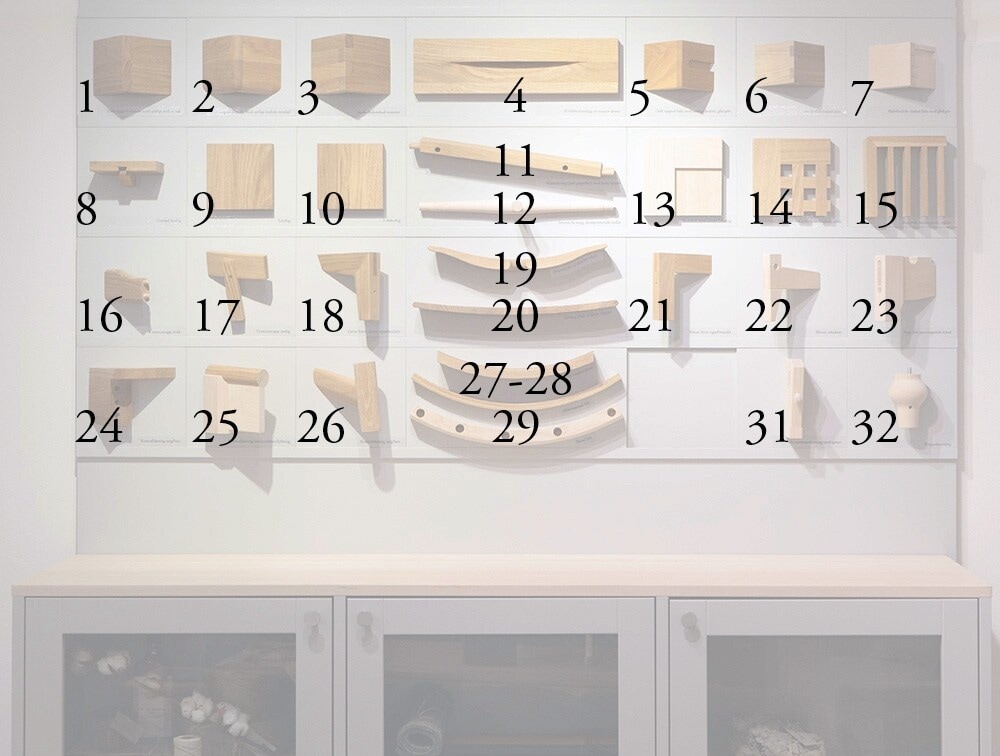

7. Half-recessed drawer with glide track

Half-recessed sink with dovetail. A beautiful and highly labor-intensive construction that provides extraordinary durability. Machine-sinked, the grooves are milled in a sink machine. Such a drawer practically never breaks.

Furniture: Small table with drawer

8. Graduated glue joint

Gradation is a joint with a groove in one of the workpieces. The graduated glue joint is used in furniture where there is a free glue joint, for example on tables with extensions, wide dining tables, and wooden coffee tables. Tabletops can move up to 15 mm in width throughout the year, depending on changes in humidity and temperature. Therefore, a solution with a graduated rule is required, allowing the wood to move along it, as the graduated glue joint allows the wood to shrink and swell without cracking.

Furniture: Wide dining table, Extendable table

9. Glue joint

For many pieces of solid wood furniture, wider surfaces are needed than can be obtained from a single plank. Glue joints are boards consisting of several lamellas (wooden slats). In short, a glue joint means that narrower pieces are glued together to reduce tension in the wood. The lamellas with the same wood grain direction are planed and glued together to form a durable and flexible wood material suitable for many applications, such as tabletops, shelves, and cabinet sides. Glue joint boards can be manufactured in various designs, wood types, and sizes. Note that Norrgavel's glue joints are of extremely high quality and cannot be compared to a countertop purchased from a hardware store.

Furniture: Almost all Norrgavel furniture

10. Triple-layered joint

Three-layered joint is an alternative to grading. Used for boards where one doesn't want a rustic feel (no list on the back). The three-layered joint is somewhat similar to plywood but made of solid wood. Thanks to thin dimensions on each layer, a very strong construction is achieved – a dimensionally stable solution without a graded list. The three layers of the joint can be glued either parallel or perpendicular.

Furniture: Kubik (door), Massiv (panel door)

11. A sheared coffin

Compare this furniture detail to a propeller. This frame is sheared to connect, without any difference in level, to the front and back legs of the chair, even though they have different inclinations. The blank is produced in one solid piece and has fixed pins in the same piece. As a result of the shear, the frame is thinner at one end compared to the other side.

Furniture: Chair

High-quality joinery - the side frames are propeller-shaped and the seat is concavely glued like a whisky barrel. The chair is polished by hand.

12. Turned leg brace, compressed ends

The shape of the legs is turned and the ends are compressed, which means that the wood is pressed together slightly. Note the grooves in the compressed ends. These ensure that the glue is evenly distributed over the entire tenon, which then swells to maximise the bond. A design that provides long-lasting durability.

Furniture: Norrgavels pin furniture