February, 2010

From sketch to customer

Quality has many dimensions. Norrgavel's founder Nirvan Richter, then an architect, longed in the early 1980s for the qualities he experienced in the furniture from his father's home region in Dalarna.

After training as a cabinetmaker at Malmstensskolan, he created his first furniture pieces. It was a way to express his vision of a different way of organizing his life. Since then, Norrgavel has taken great care in the entire process from tree to finished furniture.

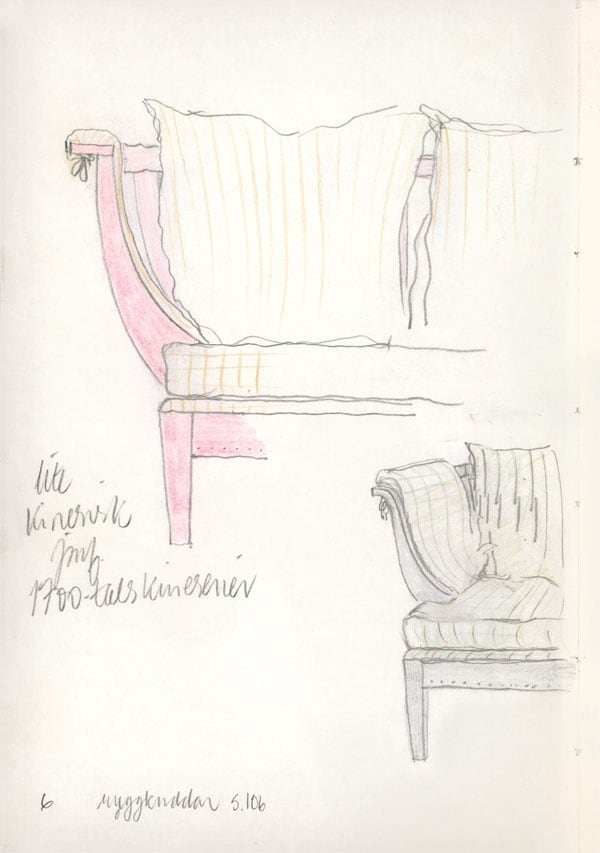

The shape of the furniture comes to Nirvan Richter when he deeply relaxes during yoga and meditation, from where he records images and thoughts in his sketchbook. The type of furniture to be developed - product development - can be a result of customer requests or come from Nirvan's vision.

The first step in product development is for Nirvan to communicate with his colleague, cabinetmaker Tomas Fröding. They are very synchronized after having worked together for 15 years (as of 2010). Tomas' base is the workshop one floor down from Nirvan's office, which facilitates the close dialogue when Nirvan's vision is to be realized in a finished prototype.

- It's only when you have the wood in your hands that things happen, when you feel its possibilities and limitations. Nirvan can describe how it should feel when sitting in a chair, how the wood should wrap around you in the lumbar region, how it should feel when the arm rests on the armrest. The feeling cannot be drawn. A millimeter adjustment can determine whether a piece of furniture becomes perfect or not, says Tomas Fröding.

The furniture is created in full scale in the carpentry workshop. Then, the right manufacturers are hired for that specific piece of furniture. The production is customer-order driven, and the surface treatment is done specifically for each customer at Norrgavel's own facility in Lammhult, which requires advanced logistics.

The moments involved in crafting each piece of furniture are numerous, requiring craftsmanship at several stages. For example, it takes two hours for an upholsterer to make the fixed seat of the lounge chair. Great care is taken with the details, such as the key for the bureau, which is crafted by a silversmith.

Norrgavel's furniture contains as few different materials as possible, always opting for natural materials. In sofas like the 85 and 100, materials include wood, cotton, rubber from rubber plants, and jute from the plant kingdom. From the animal kingdom, there are feathers from suppliers that ensure ethical treatment of animals, as well as horsehair and wool primarily sourced from Nordic sheep. From the mineral kingdom, there is iron refined into various steel alloys.

- What we manufacture should be able to return to nature. I want to feel like I could throw the furniture into the beautiful lake by my father's ancestral home in Dalarna without hesitating about whether it would be harmful to the environment or not, says Nirvan Richter.

Image from Nirvan's sketchbook, January 13, 1992